CERAKOTE

™

WHAT IS CERAKOTE?

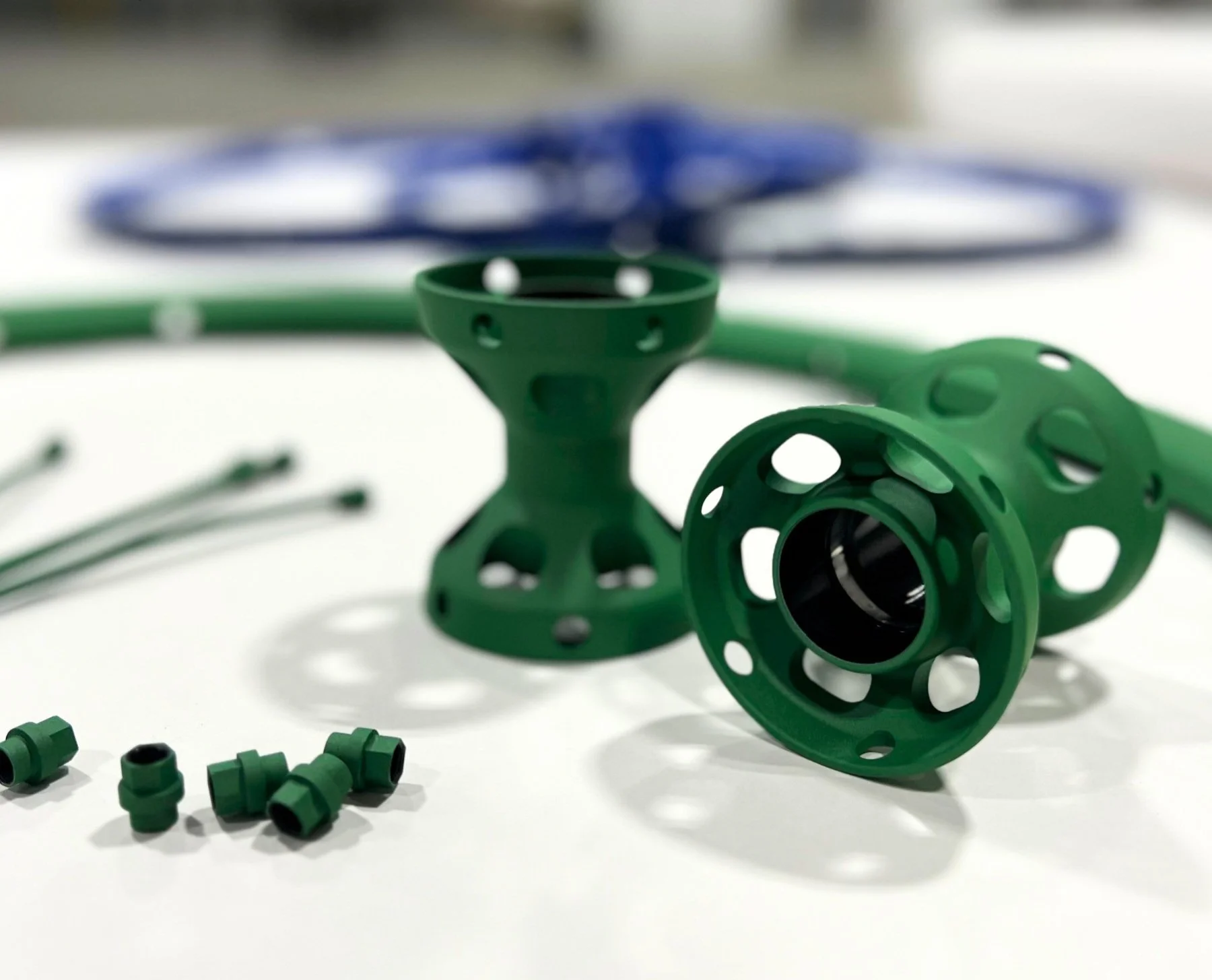

Cerakote is a ceramic-based, thin film Cerakote Finishing for a wide range of industries, products, and substrates.

Renowned for its durability and protection, strengthens surfaces against wear, corrosion, and chemicals. Its thin polymer-based coating offers superior abrasion and chemical resistance, catering to both industrial and consumer needs.

Cerakote can be used on almost every surface, so long as it goes through surface preparation processes to ensure an optimized finish.

KEY PERFORMANCE BENEFITS

-

Our industrial coatings are specially designed to endure tough conditions, ensuring your equipment remains safeguarded and operational for longer periods.

-

Guard your investments against corrosion damage. Our coatings offer strong protection against rust and other corrosive elements.

-

Our coatings are highly resistant to harsh chemicals, effectively shielding your assets from even the most aggressive substances.

-

Experience the assurance of uniform and precise color application, ensuring a seamless and professional appearance across all your equipment components.

-

No matter the temperature extremes, our coatings maintain their strength and reliability, delivering consistent performance in any environment.

-

We collaborate closely with you to grasp your specific needs, delivering tailored coatings that match your performance criteria.

-

Our coatings provide a smooth, non-stick surface comparable to Teflon® and other dry-film lubricants, while also offering superior corrosion resistance.

-

Cerakote’s thin-film design ensures maximum corrosion protection, even on surfaces with tight tolerances.

Let’s Work Together.

Interested in working together? Fill out some info and we will be in touch shortly!

FAQs

-

Cerakote offers superior durability and versatility compared to traditional finishes. It provides excellent protection against rust, scratches, and harsh environmental conditions while offering a wide range of colors in addition to Cerakote's mixology option to create your own custom colors.

-

Cerakote can be applied to a variety of materials, including metals, plastics, polymers, and more. Common applications include firearms, knives, automotive parts, aerospace components, and outdoor equipment, sporting goods.

Common Substrates:

Aluminum

Plastics

Stainless

Mild Steel

Titanium

Magnesium

-

No, Cerakote offers a vast color palette of solid colors and metallics.

Talk to our experts to learn more about Arrow’s available color selection. -

Cerakote is specifically designed not to interfere with the functionality of firearms or other equipment. It adds a protective layer without impacting performance.

-

Cerakote requires minimal maintenance. Simply clean the surface with a mild detergent and water. Avoid abrasive cleaners or solvents that may damage the finish.

-

Cerakote undergoes rigorous testing for hardness, adhesion, impact resistance, and more. It meets industry standards for durability and is designed to withstand extreme conditions.

-

Yes, Cerakote can withstand high temperatures, making it suitable for exhaust systems, firearm barrels, and other items exposed to heat. It provides thermal stability without compromising performance.